Our Services

"We are what we repeatedly do. Excellence, therefore, is not an act but a habit" Aerospace NDT lab in bangalore, Advanced Ndt Services in Bangalore

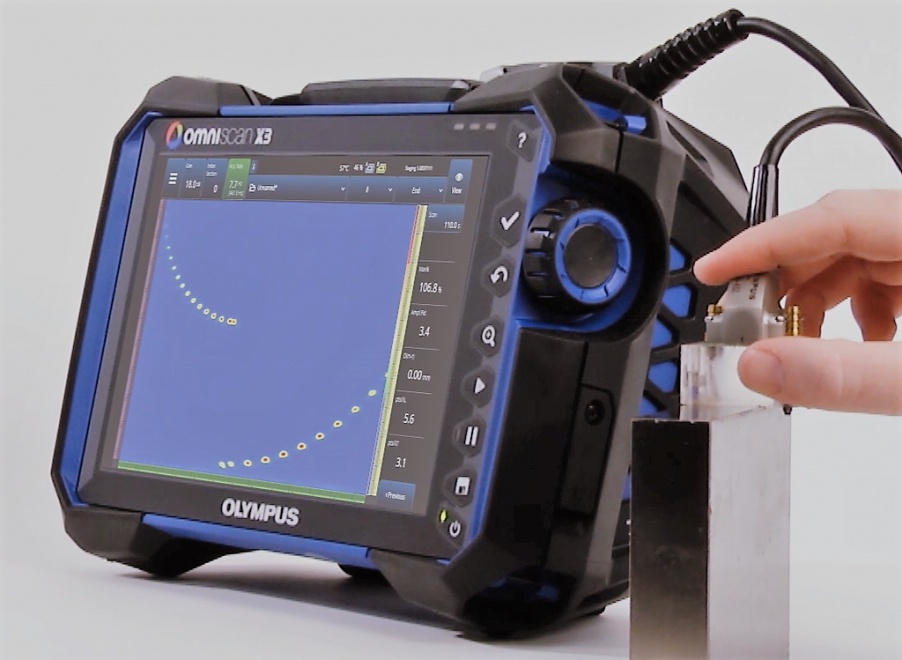

PHASED ARRAY ULTRASONIC TESTING

Olympus X3 64-128. Innovative amplitude-free live phase coherence imaging (PCI) improves small-defect sensitivity and penetration in noisy materials, all while easing your setup and simplifying sizing. Made possible by new generation electronics, TFM imaging offers better focusing capabilities for smaller indications and an improved signal-to-noise ratio (SNR). With its 128-element aperture capacity, the OmniScan X3 64 model provides enhanced image clarity. The Acoustic Influence Map (AIM) tool provides you with an instant visual model of the sensitivity based on your TFM mode, probe, settings, and simulated reflector .

ULTRASONIC THICKNESS GAUGE

The Olympus 38 DLP Thickness Gauge is a cutting-edge device revolutionizing non-destructive testing. 9+ can measure the thickness with paint, with oxidation 9+ can measure 1/4" pipe High Resolution software option of 0.001 mm or 0.0001 in. with single element transducers 2.25 MHz to 30 MHz Multilayer software option for measurements of up to four layers simultaneously High Penetration software option for attenuating materials such as fiberglass, rubber and thick casting Thickness, Velocity, and time-of-flight measurements Time-based B-scan mode; 10,000 reviewable readings per scan

EDDY CURRENT TESTING

To detect fine surface cracks in Nonferrous materials. Portable eddy current (EC) flaw detectors inspect metallic parts and perform highly reliable and advanced flaw detection of surface and near-surface defects especially in weld and cast products. Our eddy current testing equipment includes the latest advances in eddy current flaw detection for precise use in various inspection applications. In an eddy current inspection job, you need equipment you can trust. .

COMPUTED RADIOGRAPGHY

The INDUSTREX HPX-1 Plus is ideal for a lab environment where highresolution is critical with adjustable PMT and Laser Power to fine tune every image for optimum capture every time. The HPX-1 Plus also has the capability to handle extra-long plates – ideal for aerospace applications. No Dark room Process and leads Environment friendly Easy to share the images and Easy to archive Automated verification to provide assurance to customers and auditors of image integrity and authenticity. Accepts custom cut plates and rigid cassettes. .

DIGITAL RADIOGRAPHY

Digital radiography is an advanced technology based on digital detector systems in which the x-ray image is displayed directly on a computer screen without the need for developing chemicals or intermediate scanning. Shorter exposure times-almost 40% lesser time as compare to Conventional RT Enhanced SNR and linearity-Signal to Noise ratio can be easily control Reduced inspection time as no chemical processing of film is requiredNo additional process Digital image enhancement and data storage-Easy to archive or share the images.

DIGITISER

Digitizer is the equipment of choice for users who demand the highest image quality for non-destructive tests and examination radiographs. Using precise optics and a helium neon laser captures your industrial radiographs with speed, accuracy, and reliability. High quality digitized images. Post digitisation eliminates film storage. Download digitized image on any media via FTP server in case of urgency. Customized solutions. Highest Precision Digitization. Laser point to point digitiser.

Radiography Testesting with SE-75

Selenium-75 Source Radiographs are having much better definition and contrast like X-Ray radiographs. Se-75 Radiography work is seldom available in India. Selenium-75 (Se-75) and Iridium-192 (Ir-192) are both commonly used radioactive isotopes in industrial radiography for non-destructive testing. Each has its advantages and disadvantages, depending on the specific application. Lower energy emissions: Selenium-75 emits lower energy gamma rays compared to Ir-192.

ULTRASONIC TESTING

Ultrasonic Testing services for raw materials, rolled products, casting, forging and welding. Contact testing carried out at client locations and at sites.

RADIOGRAPHIC TESTING

Radiographic Testing by using Iridium-192 Gamma Ray and Portable X-Ray machines. Jobs carried out by BARC Certified Non Destructive Testing(NDT) Level-I and Level-II Technicians.

PENETRANT TESTING

Both visible red dye penetrant and fluorescent penetrant inspections at client locations as well as at our lab. Fluorescent Penetrant Inspection...

MAGNETIC PARTICLE TESTING

MPI crack detection for using Head shot and Coil shot. MPI available with visible wet particles and Fluorescent wet particles.

VISUAL TESTING

Visual Testing is perhaps the oldest and most widely used inspection technique. Often the eyes of the inspector are the only “equipment“ used for the inspection.

Why Choose Us

“ Pallakki Ndt Excellence Center Reviews from various Industry Experts “

PALLAKKI NDT EXCELLENCE CENTER PVT LTD providing ASME U Stamp and ASME U2 Stamp NDE Consultancy since last 28 years in INDIA.

PALLAKKI NDT EXCELLENCE CENTER PVT LTD have NADCAP accredited word class NDT facilities in FPI-Aerospace and MPI-Aerospace and NDT lab in NADCAP Accredited NDT Lab list. ASME Team leaders, AIS, and AI will review the NDT procedures, reports, and results to verify compliance with the ASME code. They will check for: - Proper implementation of NDT techniques. - Adequate training and certification of NDT personnel. - Correct interpretation of NDT results. - Documentation of any non-conformities and corrective actions taken. Ensuring Safety and Reliability: The ultimate goal of NDT in the ASME U and U2 stamp audit process is to ensure the safety and reliability of pressure vessels. By detecting potential defects early, NDT helps prevent failures that could lead to catastrophic consequences.

PALLAKKI NDT EXCELLENCE CENTER PVT LTD, ADAPTING NEWER NDE TECHNOLOGIES TO MEET GLOBAL REQUIREMENTS. Pallakki NDT Service distinguishes itself through a unique blend of unparalleled expertise, cutting-edge technology, and a client-centric approach. Our seasoned professionals, equipped with the highest NDT certifications, ensure precision in every evaluation. We set industry benchmarks by integrating the latest methodologies and maintaining a commitment to excellence. Pallakki's state-of-the-art facilities and comprehensive suite of services surpass conventional standards, offering clients a reliable and innovative partner in Non- Destructive Testing. With a focus on quality, efficiency, and tailored solutions, Pallakki NDT Service stands out as a trusted leader in the NDT landscape, ensuring the success of every project..

WHY WE NEED ADVANCED NDE? Advanced Non-Destructive Evaluation (NDE) techniques are essential because they offer enhanced capabilities in inspecting and assessing materials and structures. Traditional NDE methods have limitations in terms of sensitivity, speed, and accuracy, which can lead to undetected defects and increased safety risks. Advanced NDE techniques, such as phased array ultrasonics, eddy current arrays, and digital radiography, provide superior precision, quicker results, and the ability to examine complex structures. They are crucial for ensuring the integrity of critical components in industries like aerospace, oil and gas, and manufacturing. These techniques not only improve safety but also reduce downtime and maintenance costs, making them indispensable for modern industry.

“PALLAKKI NDT EXCELLENCE CENTER PVT LTD is NADCAP and NABL-2017 Accredited, AS 9100-2016, ISO 9001 - 2015 Certified and DGAQA approved company in NDE services. “

WHY PALLAKKI NDT FOR YOUR NDE NEEDS

Choosing Pallakki NDT Excellence Center Pvt Ltd for Non-Destructive Evaluation (NDE) needs is a strategic decision based on several compelling factors:

EXPERIENCE AND EXPERTISE

Pallakki NDT Excellence Center boasts a team of seasoned professionals with extensive experience in NDE techniques.

CUTTING EDGE TECHNOLOGY

Pallakki invests in the latest equipment and methodologies, ensuring clients benefit from state-of-the-art NDE solutions.

COMPREHENSIVE SERVICES

Pallakki provides a wide range of NDE services, covering various industries such as aerospace, oil and gas, manufacturing.

CLIENT-CENTRIC APPROACH

Pallakki prioritizes customer satisfaction with tailored solutions and maintaining open communication.

TRAINING AND CERTIFICATIONS

Pallakki provides NDE training for staff and clients, reinforcing their commitment to quality

education.

ACCREDITATIONS AND COMPLIANCE

The center follows industry standards, holds accreditations, and commits to quality, safety, and regulatory compliance

EFFICIENT

REPORTING

Pallakki NDT Excellence Center is known for delivering clear and concise inspection reports promptly.

REQUEST FOR A CALL BACK

PHONE

+ (91) 9448370954

pnec@pallakkindt.com

WEBSITE

www.pallakkindt.com

.jpg)

.jpg)