- Conductivity Measurements for Non Ferrous materials

- Conductivity Measurements for the Verification of Heat Treatment

- Thickness Measurements of Nonconducting Coatings on Conductive Materials

- In-service inspection of non ferrous heat exchangers and steam generators

- General purpose static eddy current tests

- Rotating probe / dynamic tests and Material sorting

EDDY CURRENT TESTING

EDDY CURRENT TESTING

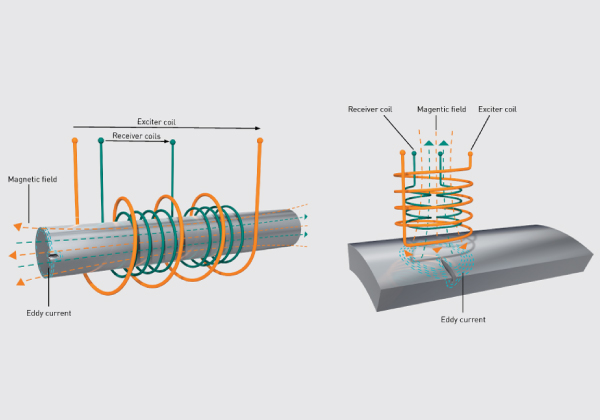

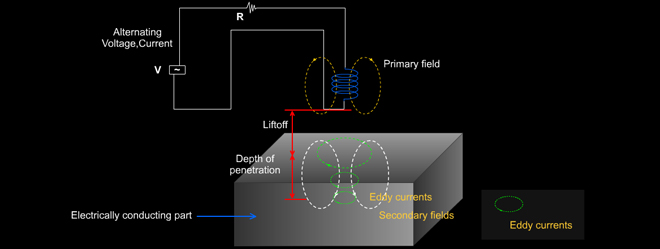

Basic Principles:

Eddy current testing is based on the physics phenomenon of electromagnetic induction. In an eddy current probe, an alternating current flows through a wire coil and generates an oscillating magnetic field. If the probe and its magnetic field are brought close to a conductive material like a metal test piece, a circular flow of electrons known as an eddy current will begin to move through the metal like swirling water in a stream. That eddy current flowing through the metal will in turn generate its own magnetic field, which will interact with the coil and its field through mutual inductance. Changes in metal thickness or defects like near-surface cracking will interrupt or alter the amplitude and pattern of the eddy current and the resulting magnetic field. This in turn affects the movement of electrons in the coil by varying the electrical impedance of the coil. The eddy current instrument plots changes in the impedance amplitude and phase angle, which can be used by a trained operator to identify changes in the test piece.

Eddy Current Testing, Eddy current testing in ndt, Eddy current testing in Bangalore, Eddy current testing machine, Eddy current testing aircraft, Eddy current testing companies, Eddy current testing course, Eddy current testing certification, Eddy current testing cost, Eddy current testing companies near me, eddy current testing cost, eddy current testing for crack detection