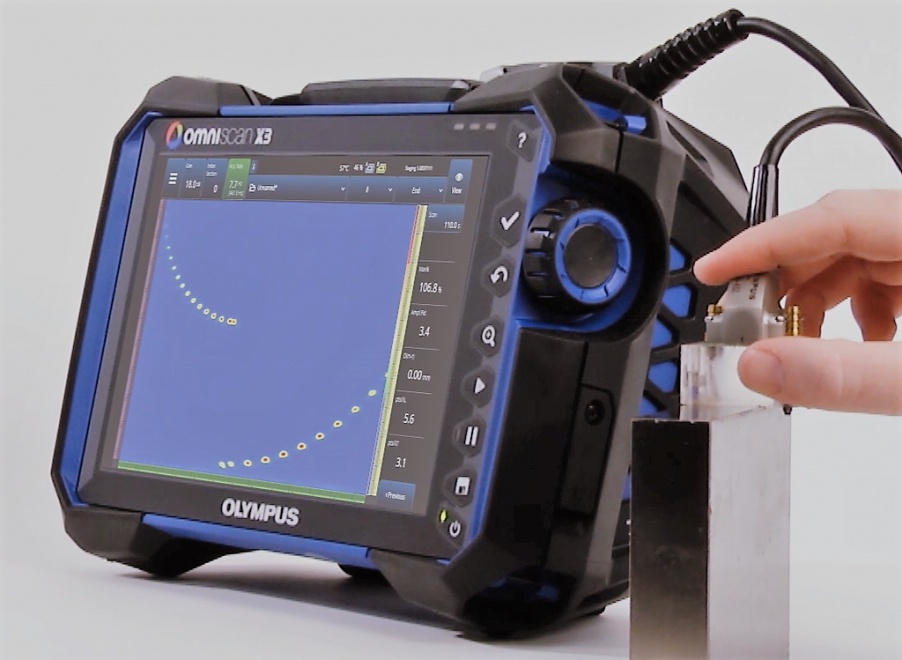

Phased Array Ultrasonics (PAUT) offers significant advancements over conventional Ultrasonic Testing (UT), making it a preferred choice for many applications:

- Enhanced Defect Detection: PAUT utilizes multiple ultrasonic beams and electronically controlled probes, allowing for precise control of the beam angles, focal points, and coverage. This results in improved defect detection, especially in complex geometries and materials with anisotropic properties.

- Single-Scan Inspection: PAUT can often replace multiple conventional UT scans with a single scan due to its ability to electronically steer and focus the ultrasonic beam. This reduces inspection time and improves efficiency.

- Versatility: PAUT is suitable for a wide range of materials, geometries, and inspection scenarios, making it a versatile method for flaw detection and characterization.

- Data Acquisition and Analysis: The digital nature of PAUT enables easy data storage, retrieval, and analysis, with options for real-time imaging and data recording, facilitating long-term record-keeping and trend analysis.

- Reduced Couplant Usage: PAUT requires less couplant (ultrasonic gel or water) than conventional UT, reducing material waste and cleanup efforts.

- Improved Reporting: PAUT often provides more detailed and interpretable results, with advanced imaging capabilities that allow for easy defect characterization.

These advancements make Phased Array Ultrasonics an invaluable tool in industries such as aerospace, oil and gas, and manufacturing, where precise and efficient inspection is essential.

phased array ultrasonic testing, PAUT testing in Bangalore, phased array ultrasonic testing price, phased array ultrasonic testing training, phased array ultrasonic testing vs ultrasonic testing, automated phased array ultrasonic testing, phased array ultrasonic testing course, phased array ultrasonic testing certification, phased array ultrasonic test,phased array ultrasonic testing minimum thickness, phased array ultrasonic testing of welds, phased array ultrasonic inspection of welds