Aerospace Non Destructive Testing (NDT) Testing Centre at Pallakki NDT, Bangalore, India

Aerospace Non Destructive Testing(NDT) is a zero error tolerance inspection area of Non Destructive testing, where in a single escape of a defective part into running aircrafts can lead to huge disaster.

Aerospace NDT is said to be work to requirement culture where Inspectors are trained to bring new culture of thinking in (NDT) Non Destructive Testing area, aerospace ndt is needs not just simple NDT skills but requires very thorough knowledge of various specifications of various customers for which we will be working for. To be in aerospace non-destructive inspection, we are proud to attain a huge level of confidence from customers for what we do in Inspection. Aerospace domain is a small world compared to other NDT area where in Prime customers play a very important role in believing what we do.

Our NDT inspectors are specifically trained for aerospace requirement and will not be diluted with other domains to maintain the quality of inspection. Pallakki NDT has separated the aerospace domain from all other inspections to maintain dignity and quality of inspections in what we do. Pallakki NDT cautiously manages our NDT inspectors qualification and improvement due to better understanding of the liability and outcomes from the various case studies and customer feedbacks.

Importance of Aerospace NDT: Non destructive testing methods are all are common in Aerospace, Petrolium, construction industries.. but what important in aerospace is the way the inspector thinks about the results. Also aerospace NDT is closely monitored by various aerospace customers, NADCAP and AS auditors. Aerospace NDT inspectors do require more of the various specification interpretation skills at a Level-2 stages itself. The training documentation as per NAS410 is very robust enough to capture all written evidences to be submitted to customers before qualifying inspectors. Beyond the specifications customers closely monitor their requirement is the seriousness of the aerospace NDT beaty and seriousness.

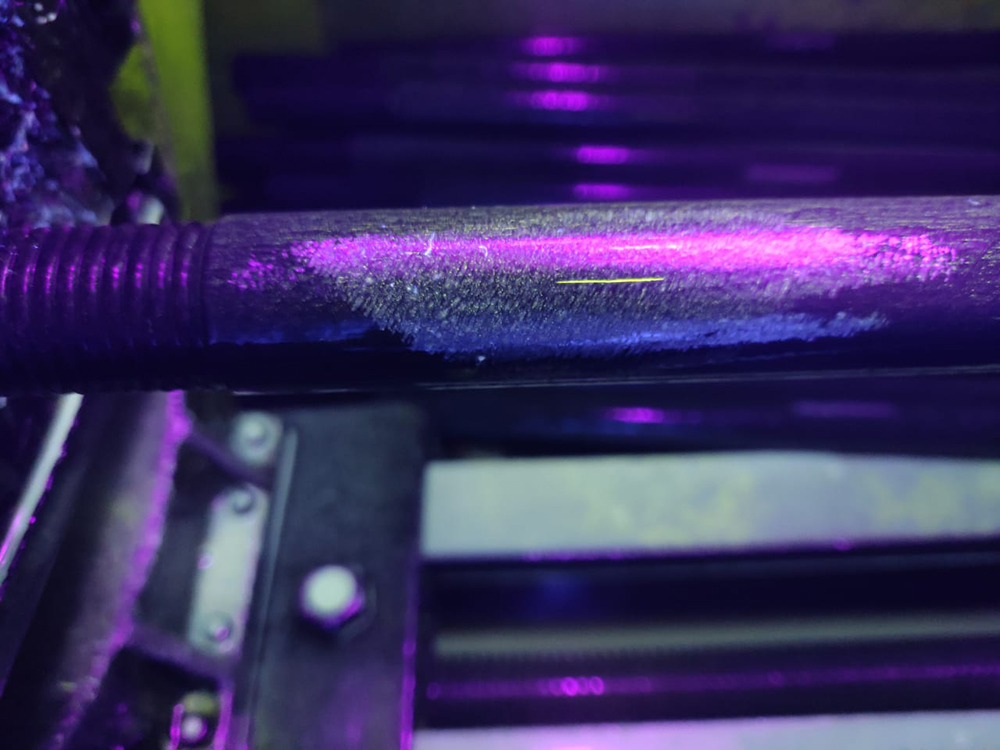

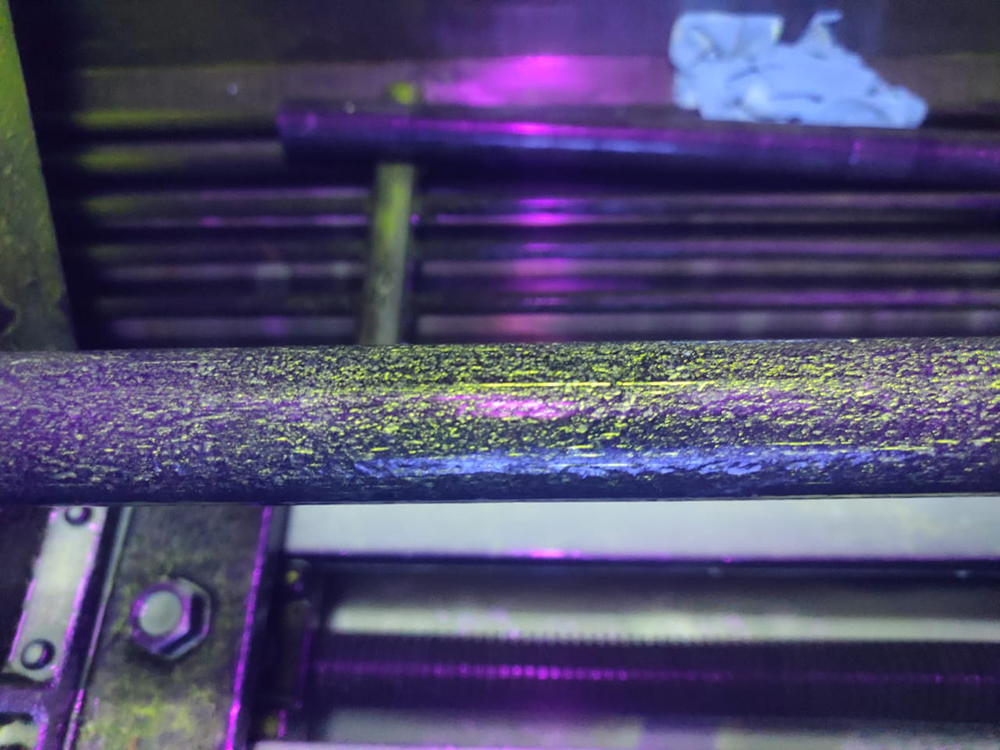

Magnetic Particle Inspection